FACTS

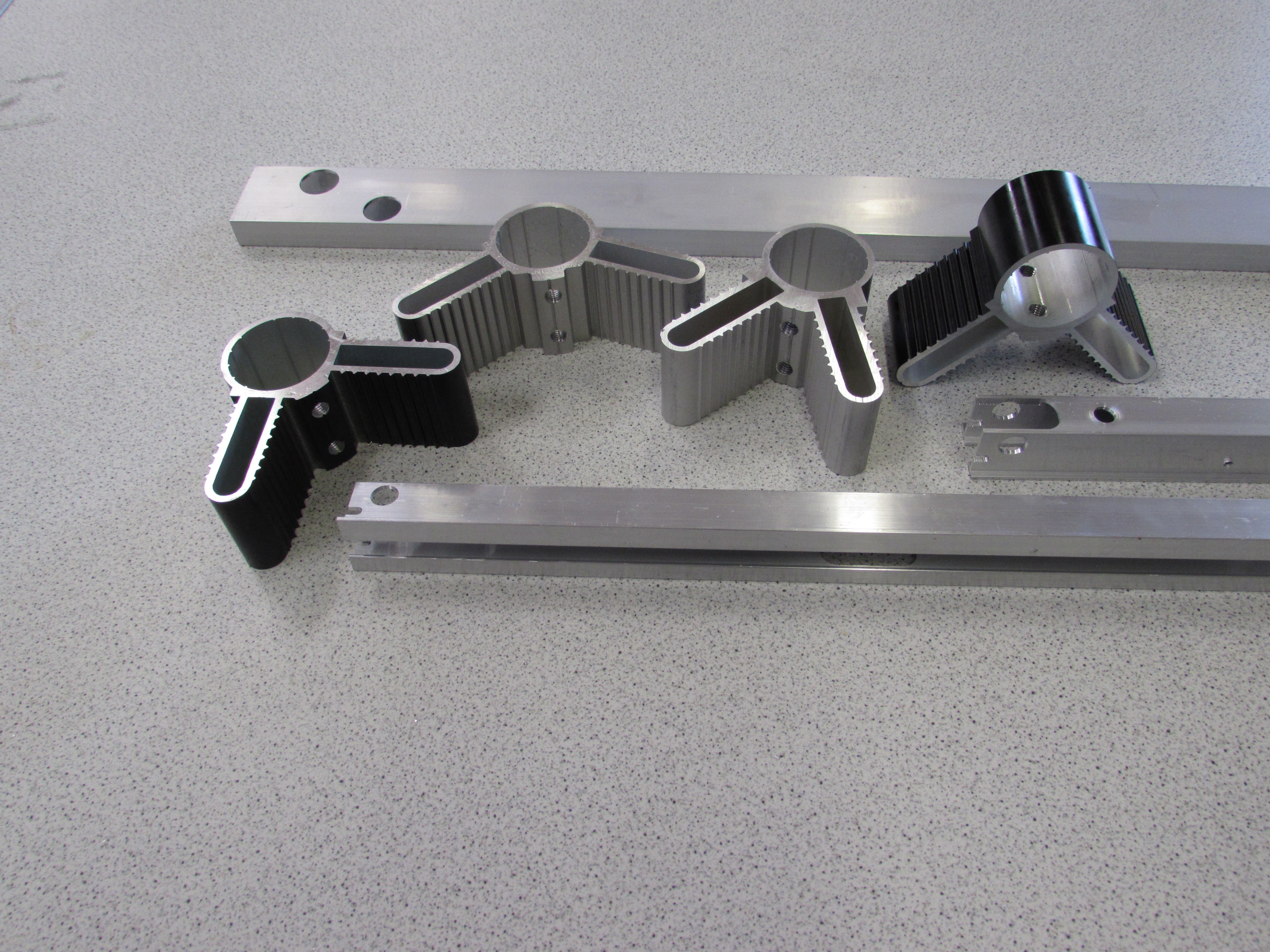

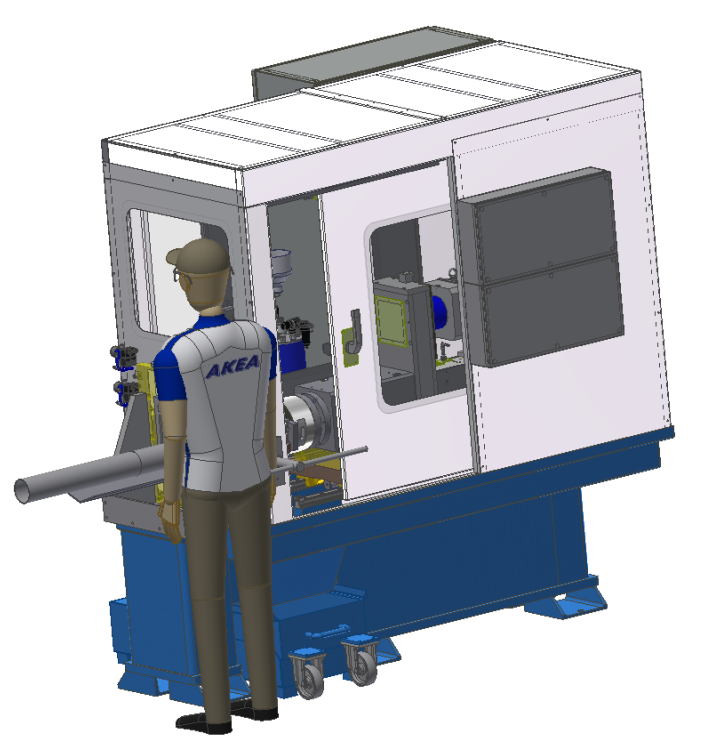

The AKEA Machining Center, is developed for efficient processing of a wide range of parts in steel and Aluminum from profiles and extrusions.

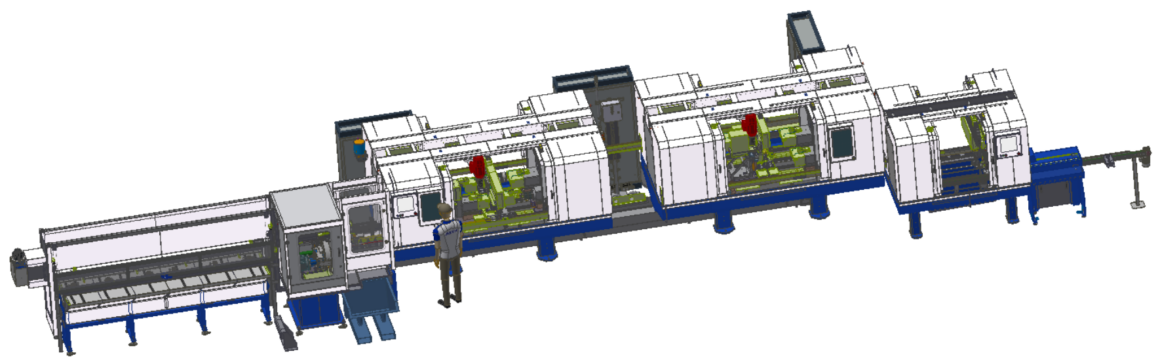

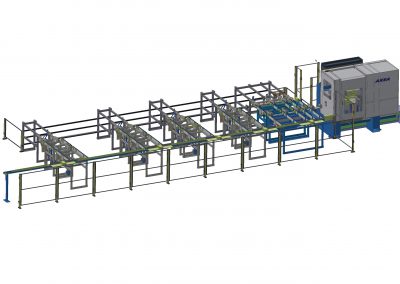

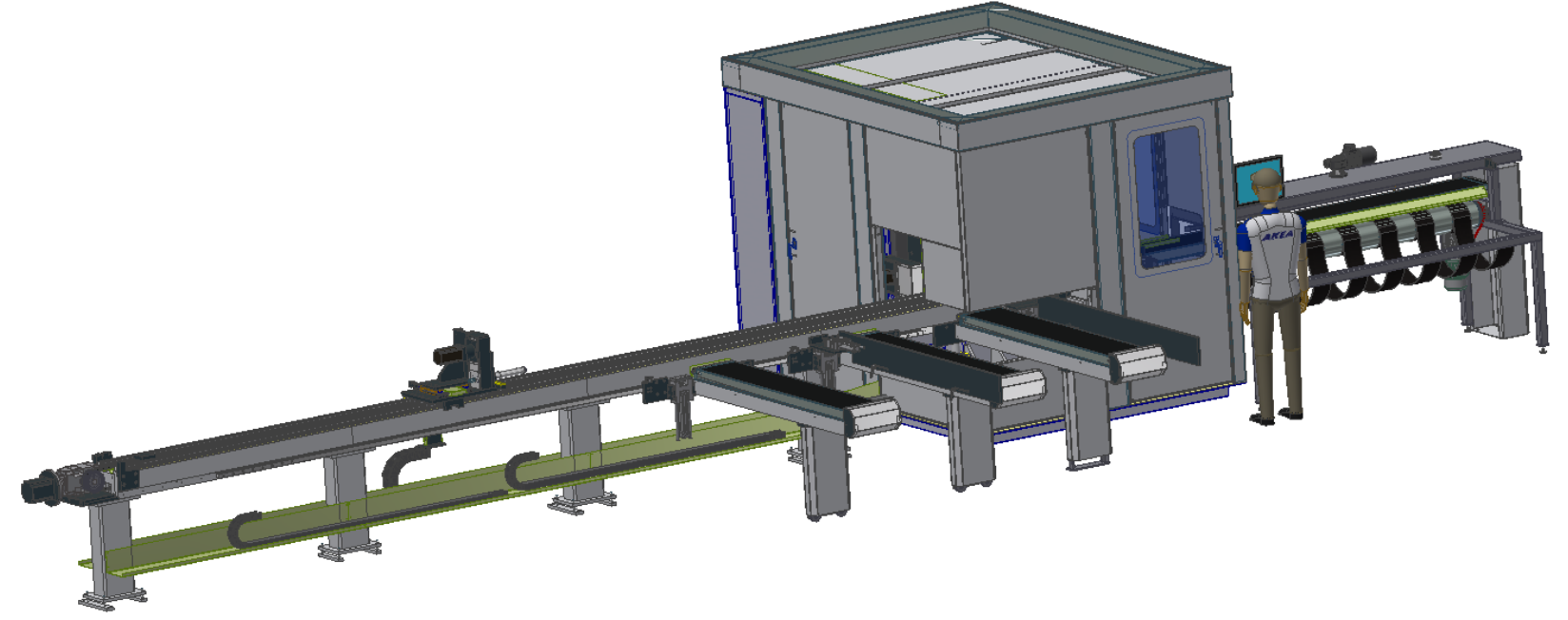

The entire process is automatic, from loading in stock length materials, to sorting and collecting the finished items. The Machining center can run unattended for long periods and is safe to run after working hours.

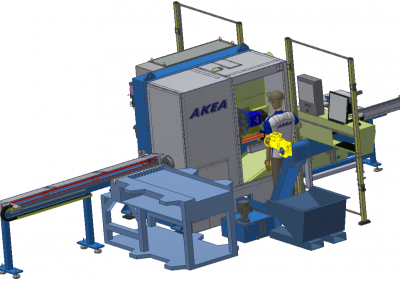

The machine consists of a 3-axis CNC machining station with a 12 station toolholder, highspeed tool exchange and a CNC miter cutter.

The machine is fully configurable with:

- Automatic loading from magazine

- Feeder Gripper with 360° profile rotation

- Automatic sorting and collecting of finished parts

Programing is made easy to learn and use, by the windows-based programming interface. The programming is parametric, where drawing information’s can be transferred directly to the interface. The system can operate with several part orders at the time and uses nesting facilities to minimize material waste.

The machining center is customer configurable and can be adapted to handle a wide range of aluminum and metal profiles.

Don’t hesitate to contact us for more info