FACTS

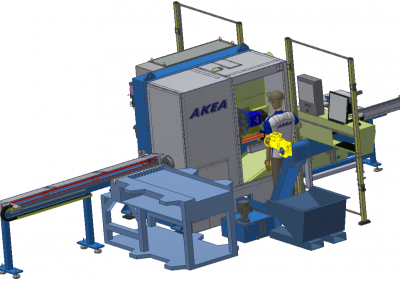

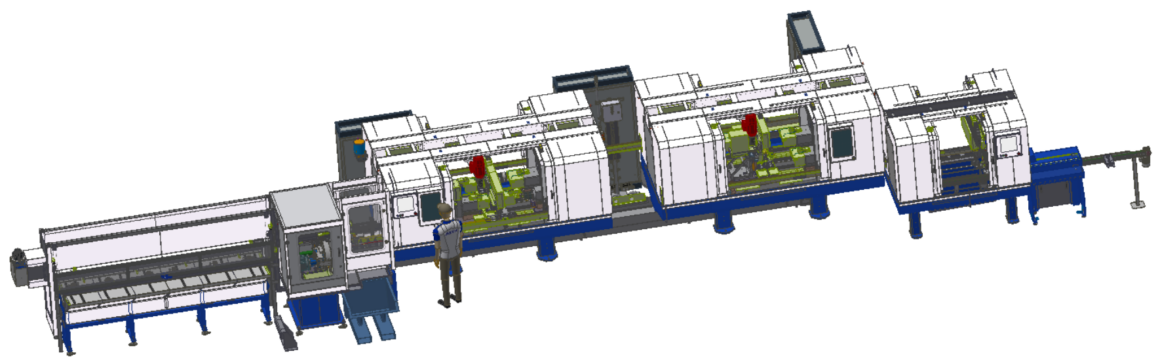

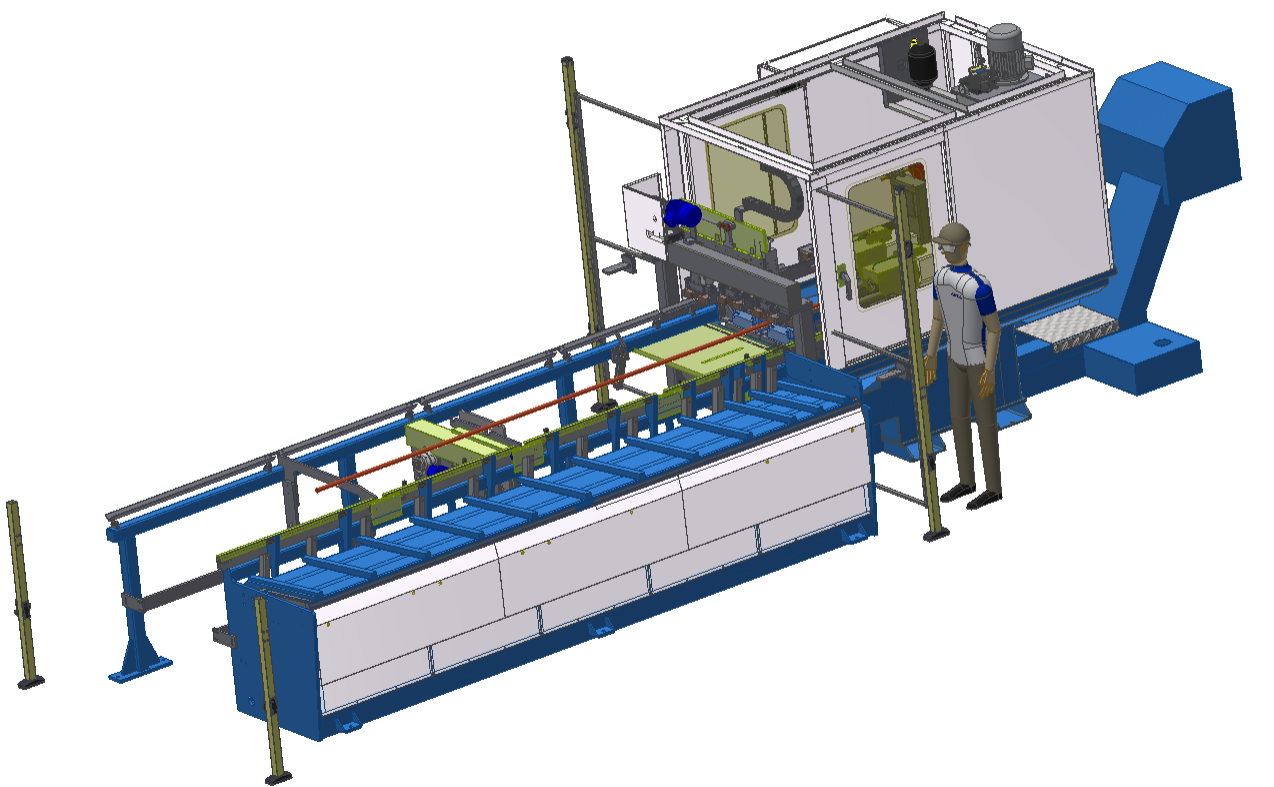

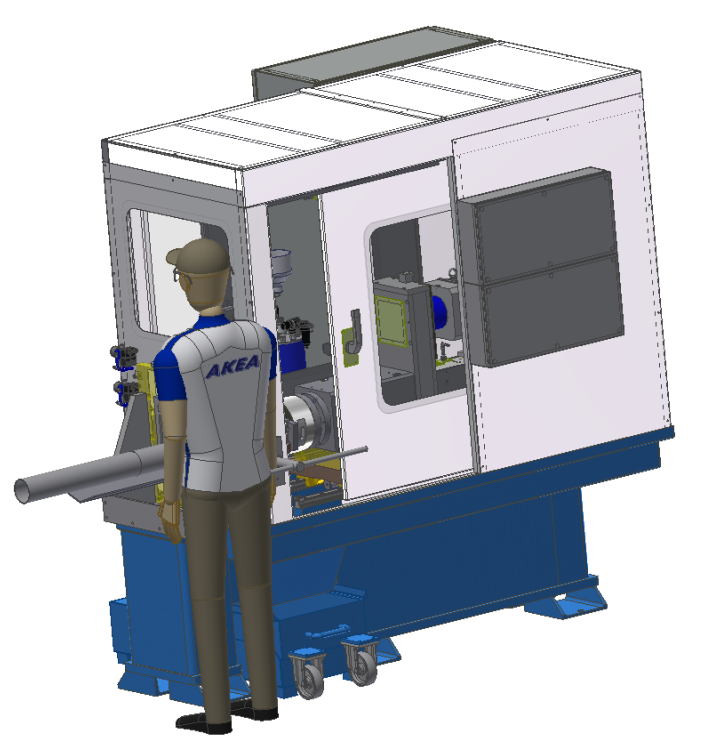

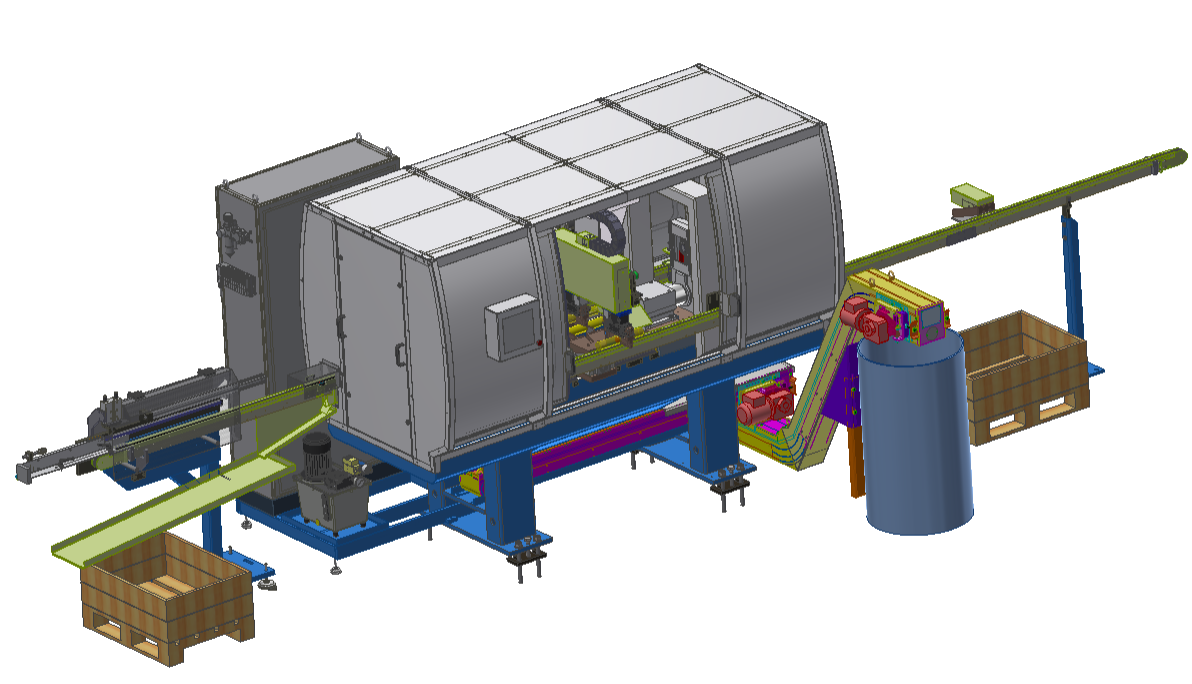

The Akea DEM Series, is a machine series of highly productive, fully automated metal processing machines, with rotating tools and a fast handling system taking the part through the machine. The machine is developed for high volume end machining operations on bar and tube materials.

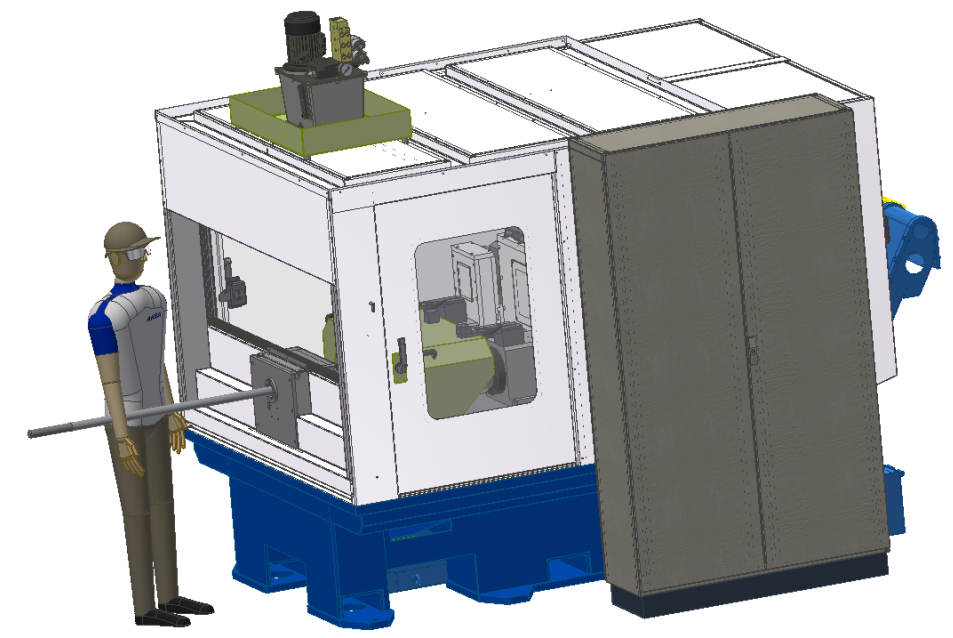

The machines are double end machines with 2 to 6 spindles working simultaneously. The machining concept ensures a high productivity and a wide range of machining possibilities. E.g. turning, drilling, chamfering, peeling, thread rolling, thread cutting and key milling.

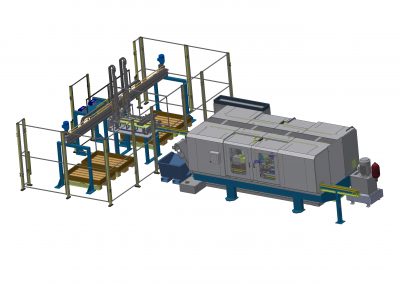

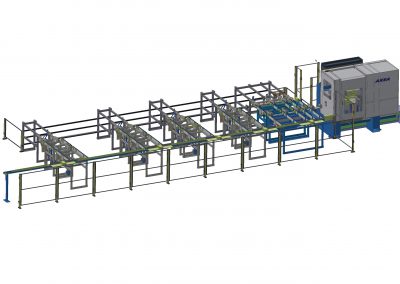

The integrated part handling system, handling parts in, through and out of the machine ensures a fully automated machining process.

Optional the machines can be integrated with a wide range of saws and delivered with a fully automated part packing system.

The operator interface for the machine is very intuitive and easy to operate. Setup time for changing between different products is minimal.

The machines is customer configurable to handle material diameters from ø4mm to ø300mm, lengths from 20mm to 1200mm.

Don’t hesitate to contact us for more info

Process tools:

- Chamfering

- turning

- Peeling

- Thread Rolling

- Thread cutting

- End machining

- Drilling

- Key milling

- Cold forming

Configuration according to process demands

- Spindles : 2 to 6

- Vices : 1 to 6

- Part length : 20mm to 1200mm

- Output : 30 to 1200 parts/hour