FACTS

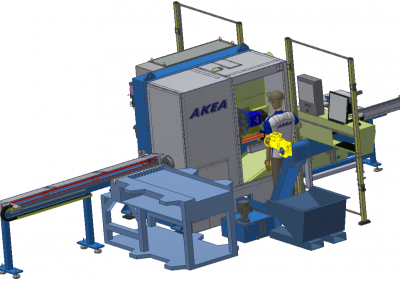

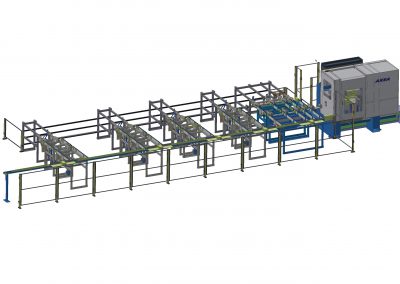

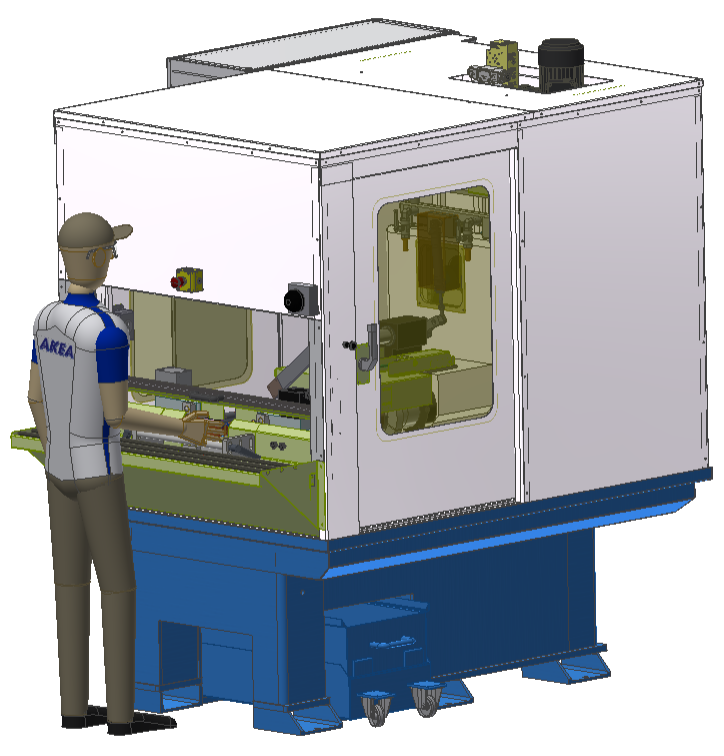

The Akea GEW 202 is a part of the Akea GEW series but modified for also processing U-bolts / Spring brackets.

The machine is like the other machines in the GEW series a productive semi-automated metal processing machine with rotating tools.

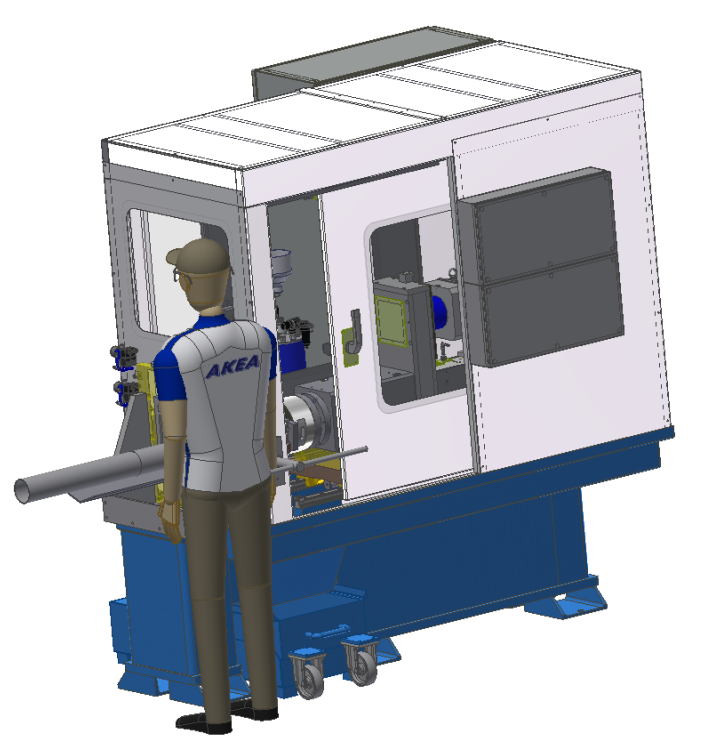

The operator interface for the machine is very intuitive and easy to operate. Setup time for changing between different products is minimal.

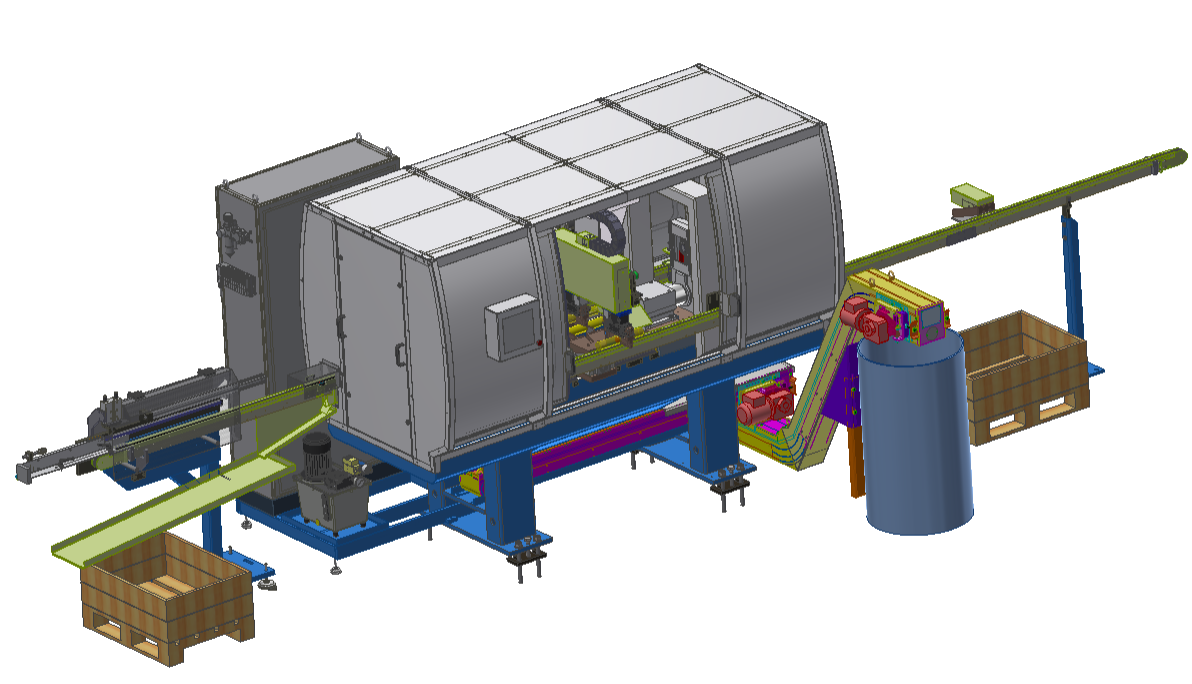

The machine series is developed for chamfering, peeling and thread rolling processes on spring brackets / U-bolts, but can also be used for processing straight rebar and bar material.

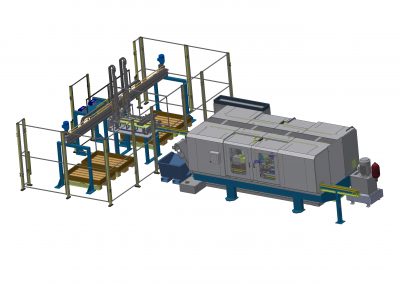

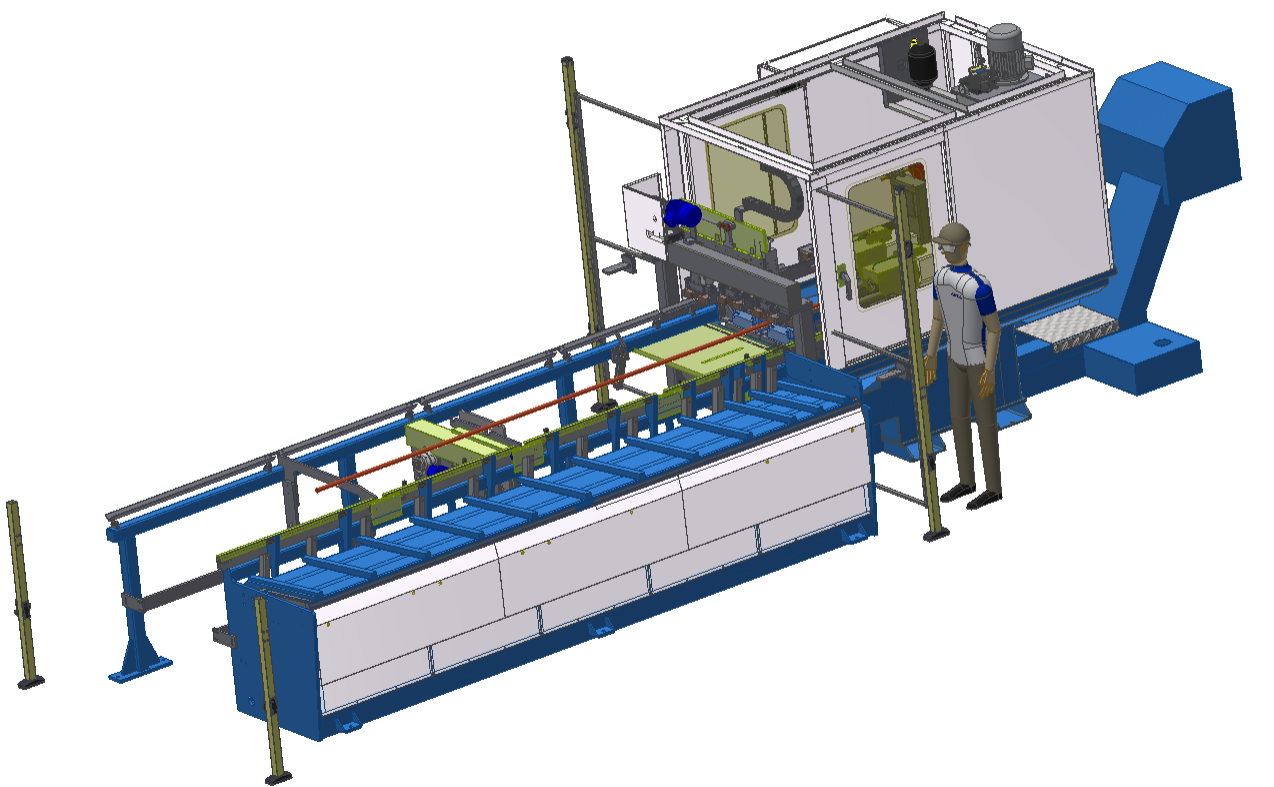

The workpieces are loaded manually by an operator where after the machine automatic perform e.g. the chamfering, peeling and thread rolling operations.

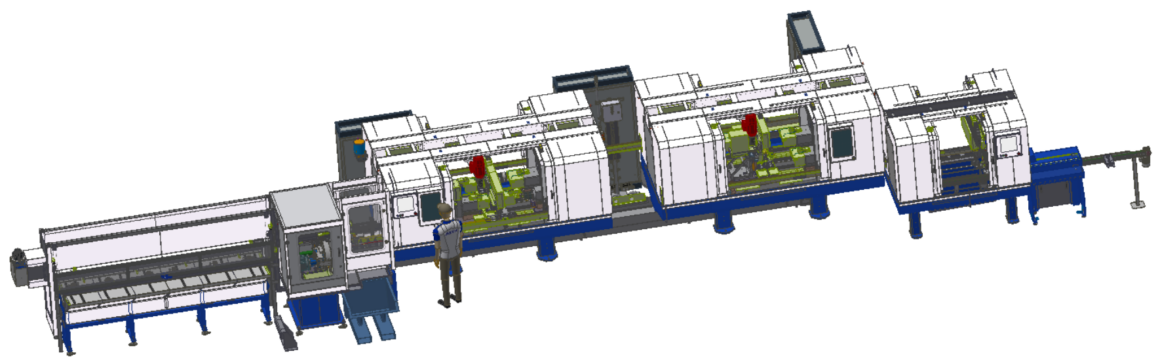

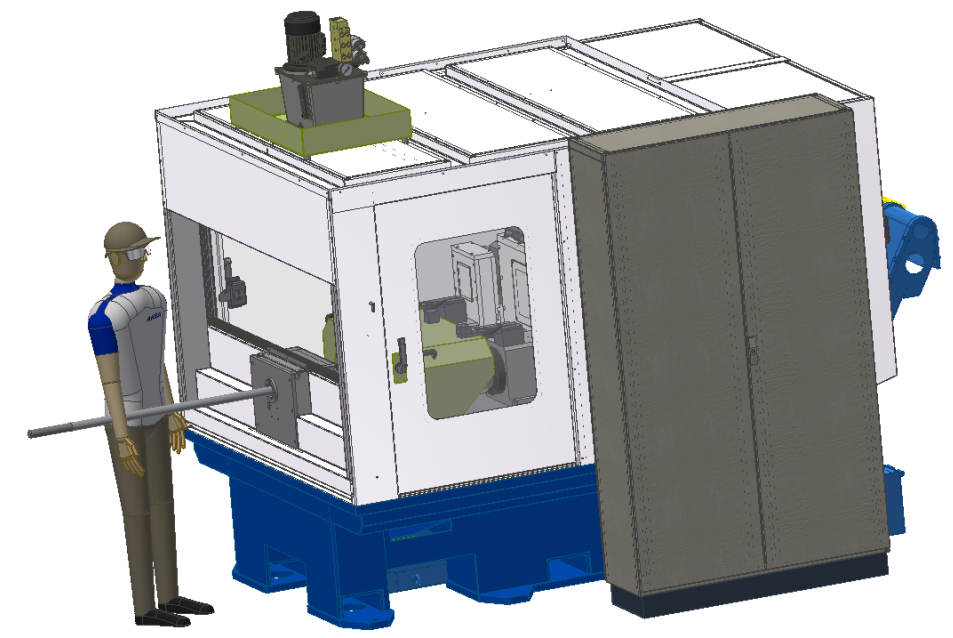

The machine is configurable with number of spindles, depending on customer processing demands.

Process tools:

- Chamfering

- Peeling

- Thread Rolling

- End machining

Configuration according to process demands

- Spindles : 1 to 3

- Vices : 1 to 2

- Thread rolling : M12 up to M56

- Part length : 100mm to 500mm

- Output : 30 to 150 parts/hour